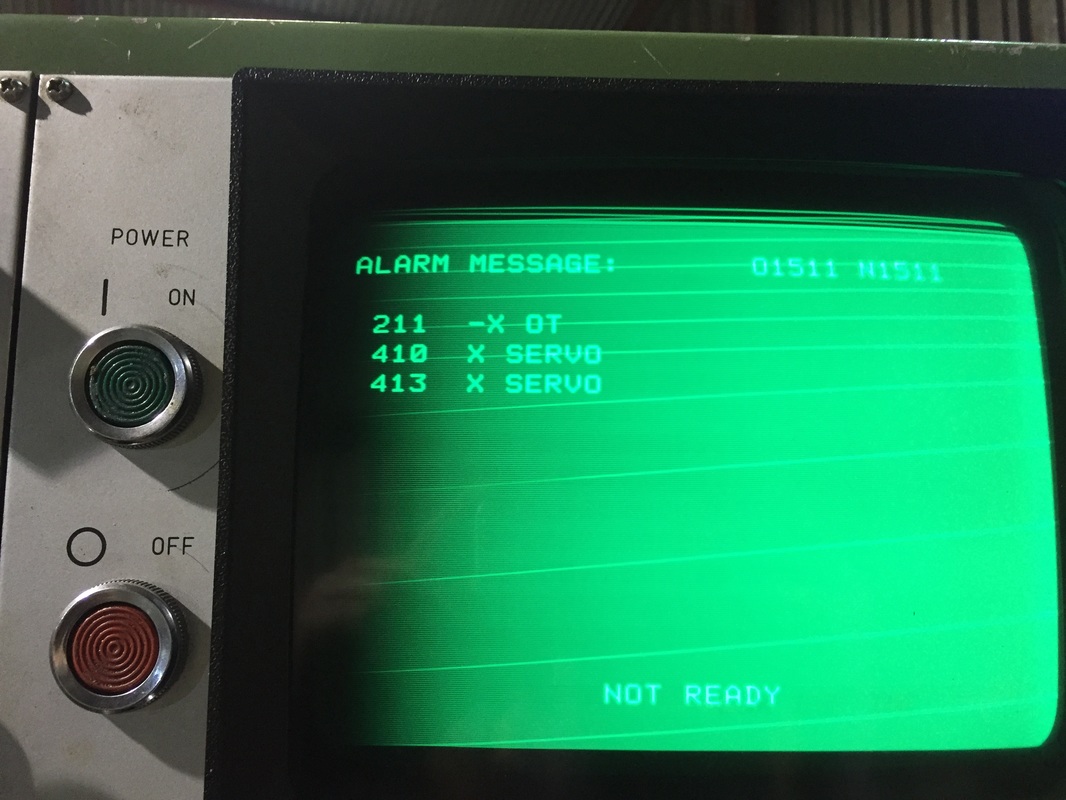

Well, it was for sale as-is. I was told that I could move the axes around and turn the spindle on. I moved Z back and forth a few inches, and then moved X up and down a few inches before I got a bunch of alarms. I backed the X axis away from the overtravel position and hoped that would clear the alarm, but it didn't. I was unable to clear the alarm and had to buy the lathe. Fortunately, I bought it for near scrap metal price. It also came with two pneumatic collet closers and a air-chuck, as well as about 10 Hardinge 215 collets.

At that point I was pretty worried about how this project was going to play out. I had hoped to use the lathe a little bit in its original configuration before going for a LinuxCNC retrofit, but I guess that just wasn't in the cards. I read the Fanuc manual and tried everything but was unable to clear the alarm and get the machine going.

At that point I was pretty worried about how this project was going to play out. I had hoped to use the lathe a little bit in its original configuration before going for a LinuxCNC retrofit, but I guess that just wasn't in the cards. I read the Fanuc manual and tried everything but was unable to clear the alarm and get the machine going.

I decided to have a look at the servo that was giving me grief and this is what I found.

So here I was with 6000lbs of worthless steel and I had to make a decision as to whether or not to invest a significant amount of time and money in a retrofit or scrap the project. After a few days of deliberating I decided to start ordering parts.

RSS Feed

RSS Feed