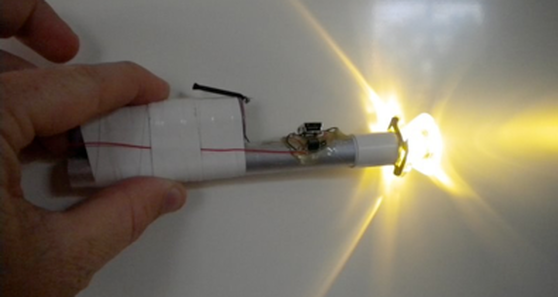

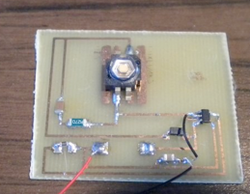

I've now added some feedback for the pilot on the trim position. We decided to incorporate the addition of this bar graph so that the trim could be set to "take-off" or other known positions. This will allow the pilot to have consistent force-feedback during take-off which is a critical portion of the flight envelope.

This is all on the dev-board still, but it is working as planned and things are moving along quickly.

This is all on the dev-board still, but it is working as planned and things are moving along quickly.

RSS Feed

RSS Feed